Sika® Galvashield® XP

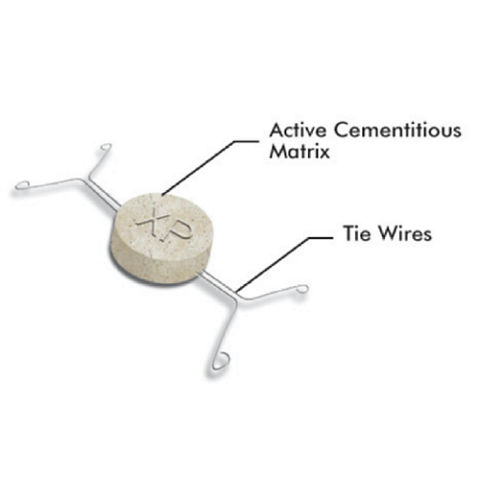

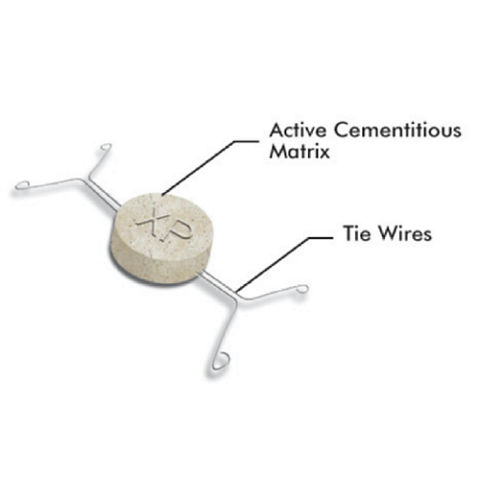

Sika® Galvashield® XP Range is available in five sizes: Compact / XPT / XP2 / XP4 / XPX embedded galvanic anodes are used in concrete repair and rehabilitation to prevent the formation of new corrosion sites adjacent to completed patch repairs. Designed for optimum performance and ease of installation, the alkali-activated (Type 1A) anodes are comprised of high purity zinc core that is activated by the surrounding specially formulated cementitious mortar with an internal pH of >14 which keeps the zinc active over the life of the anode. The anode is quickly and easily fastened to the exposed reinforcing steel using the contractor-friendly One-and-Done™ single-wire connecton. Once installed, the zinc core corrodes preferentially to the surrounding reinforcement, thereby providing galvanic corrosion prevention to the adjacent reinforcing steel and mitigating ‘ring anode corrosion' or the 'halo effect'.

- Proven technology - supported by independent test programme.

- Sika® Galvashield® XP is the original embedded galvanic anode with an extensive 20-year track record.

- Type 1A anode - alkali-activated to maintain activity of the zinc; meets building code requirements that prohibit intentionally added constituents that are corrosive to reinforcement with the repair area.

- Easy to install - innovative single wire One-and-Done™ connection can be installed twice as fast as traditional two wire connections, saving up to 50% on installation labour costs.

- Focused protection - provides localised corrosion protection where it is needed the most, at the interface of the repair and the remaining contaminated concrete.

- Cast zinc core - provides high anode utilisation and a secure long-term connection between the zinc and the integral lead wire.

- BarFit™ design - grooved edges on Sika® Galvashield® XP2, XP4 and XPX anodes assist with secure anode placement.

- Steel connection wires - provides dependable steel-to-steel contact with no intermediate materials (e.g. galvanising) that may impede the long-term electrical connection.

- Economical - provides localised protection where it is needed the most, at the interface between the repair and the remaining contaminated concrete.

- Versatile - effective in chloride-contaminated and carbonated concrete containing chlorides. Can be used for both conventionally reinforced and prestressed or post-tensioned concrete.

- User friendly - installation is quick and easy, requiring no special equipment or training.

- Low maintenance – requires no external power source or system monitoring.

- Measurable – anode performance can be easily monitored if required.

- Does not cause hydrogen embrittlement.

- ICRI CSP-3 (Concrete Surface Profile) - raised ridges provide increased surface profile to promote mechanical bond between repair mortars and concrete.

- Does not cause hydrogen embrittlement.

- Long lasting – minimum 20 year anode service life* when using standard design tables, reduces the need for future repairs.

- Full System – can be used in conjunction with Sika® FerroGard® and Sikagard® technologies to offer a total corrosion management system.

- Independent testing - indicates concrete repair service life can be extended by more than 400%.