28/03/2022

The demand for cutting-edge designs with long-lasting appeal is increasing and vehicle manufacturers are looking more and more for solutions to reduce process times and costs without compromising on quality and performance. In order to meet the growing demand for energy-saving, lightweight designs, adhesive-based joining techniques have become increasingly popular in recent years.

CUSTOMERS DEMAND OCCUPATIONAL SAFETY ALONG WITH ENVIRONMENTAL AND QUALITY STANDARDS

However, time also moves on in this field and customers are increasingly asking specifically for products that not only offer the best bonding and sealing results, but also meet the highest standards in terms of work safety and environmental compatibility. At the same time, products are expected to feature as few warning symbols as possible and provide relevant features such as the ISEGA or NSF certificate (for applications in the food industry).

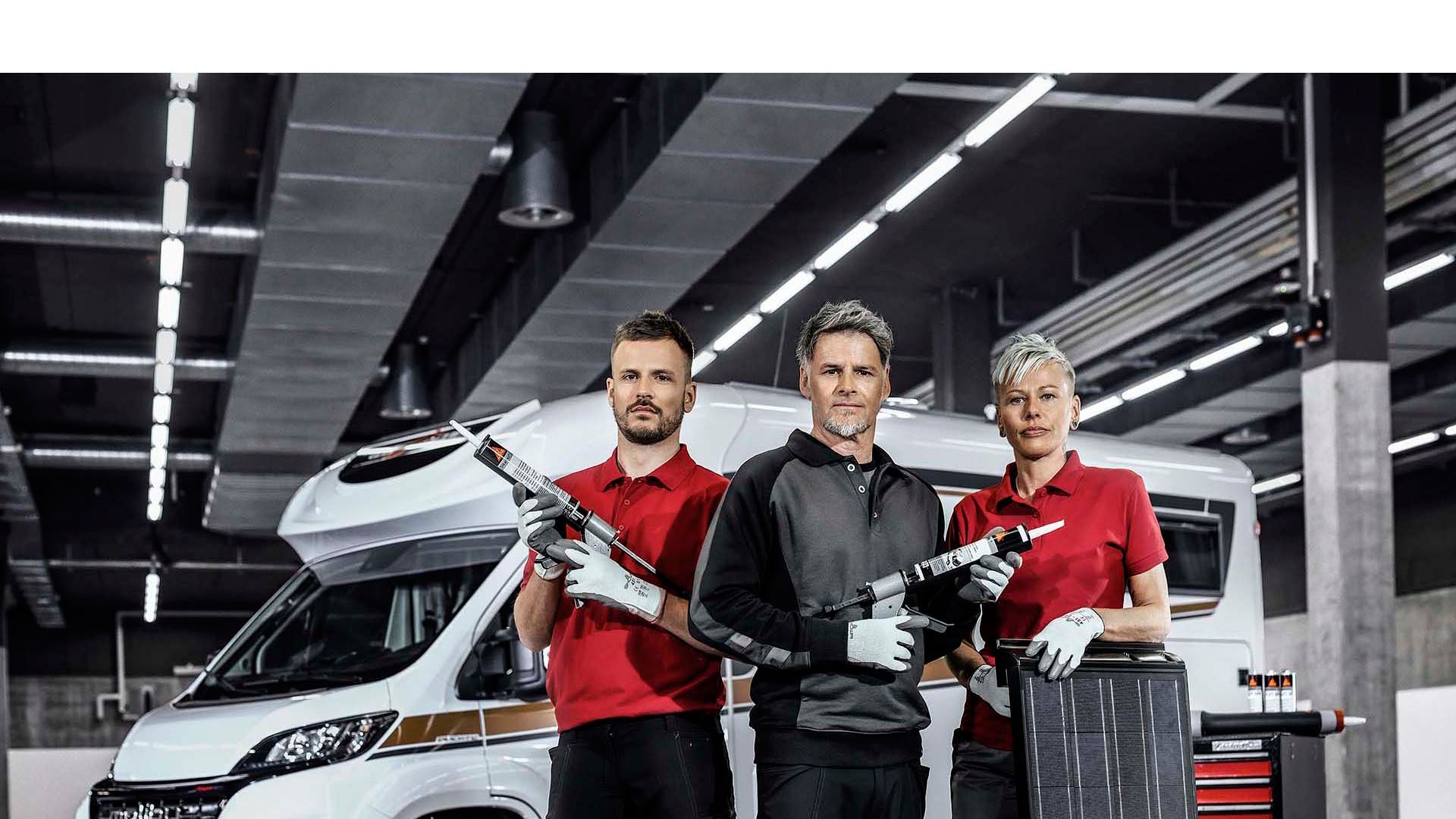

NEW ADHESIVES AND SEALANTS FOR VEHICLE CONSTRUCTION, FREE FROM WARNING SYMBOLS

For this reason, adhesive and sealant experts have expanded their range in vehicle construction by particularly low-emission products: "The Sikaflex®-500 series is largely free from isocyanate, solvents and silicones, and is partly also free from phthalates plasticizers. In addition, products showed excellent processing properties and an outstanding adhesion spectrum, even without pre-treatment. Sika’s proprietary patented adhesive technology based on silane-terminated polymer (STP) creates the prerequisites for this. It does away with a number of hazard symbols that otherwise typically confront users. Combined with the time savings brought about by no longer needing primer pre-treatment, the unlabelled design of the Sikaflex®-500 series makes handling easier while at the same time opening up new application opportunities in sensitive areas such as the food industry."

FOUR SOLUTIONS FOR BONDING, SEALING, AND PROTECTING

Sika has therefore added four new products from the Sikaflex®-500 series to its range of vehicle construction products.

As a result of the very limited amounts of required pretreatment, the flexible Sikaflex-554 assembly adhesive offers the advantage of time savings in its standard version. A fast cure version based on Sika’s PowerCure technology is able to achieve even faster handling times.

For assemblies where components need to stay in place instantly, Sikaflex®-545 is the solution that makes use of spacers and tapes obsolete. Sikaflex®-545 bonds without primer to a broad range of materials such as glass, metals, metal primers, GRP and paint coatings.

The weather-resistant adhesive and sealant Sikaflex®-522 boasts a broad spectrum of adhesion on different substrates and is ideally suited for almost all indoor and outdoor sealing applications. Thanks to the ISEGA food certificate and particularly good mould resistance, it can also be used in wet areas and in the food industry.