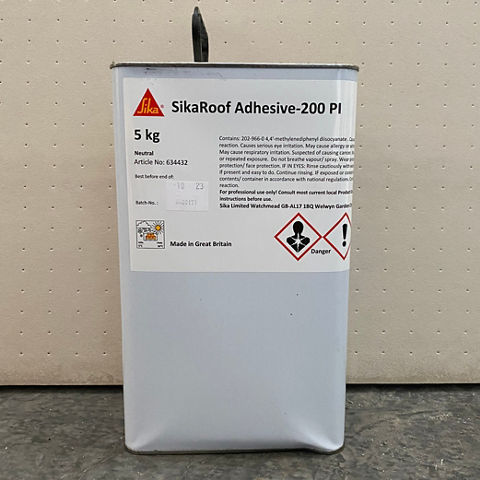

SikaRoof® Adhesive-200

Polyurethane foam adhesive for bonding roofing insulation boards

SikaRoof® Adhesive-200 is a polyurethane 1- part, bead applied, moisture curing foam adhesive that bonds insulation boards to various types of construction material substrates.

- Adheres to solid, clean and dry or slightly moist surfaces

- Easy application

- Applied directly out of the container

- Good adhesion to many construction materials