SikaRoof® Adhesive-400 Spray

SikaRoof® Adhesive-400 Spray is a 1-part, polyurethane based, moisture‐curing, spray applied contact adhesive in a pressurised canister system.

- Quick adhesive applications using pressurised canister and spray gun

- Less wastage of adhesive due to pressurised container

Usage

- Sprayable adhesive to bond Sarnafil G membranes to specific substrates

Advantages

- Quick adhesive applications using pressurised canister and spray gun

- Less wastage of adhesive due to pressurised container

Packaging

| Packaging unit | Single canister 19,4 kg (Adhesive 13,3 kg) |

| Packaging dimension | Cardboard box 320 mm × 320 mm × 460 mm |

|

|

|

|

Refer to current price list for packaging variations

Product Details

Chemical Base

Polyurethane moisture‐curing

Shelf Life

12 months from date of production.

Storage Conditions

The product must be stored in original, unopened and undamaged sealed packaging in dry conditions at temperatures between +5 °C and +25 °C. Always refer to packaging.

Consistency

liquid

Compatibility

Not compatible in direct contact with EPS/XPS insulation boards, copper plate, bituminous substrates, waterproofing membranes (thermoplastics/elastomers) excluding soft PVC. These materials could adversely affect the product properties.

Application

Ambient Air Temperature

At least +5 °C

Substrate Temperature

At least +5 °C

Open Time

| Temperature | Open Time Tgel |

| +30 °C | 10 minutes |

| +20 °C | 20 minutes |

| +10 °C | 30 minutes |

| +5 °C | 40 minutes |

Note:These times may vary due to ambient conditions.

Consumption

| Non-porous substrates | ~150–200 g/m2 |

| Porous substrates | ~400 g/m2 |

One single canister covers ~80–100 m2

These figures are theoretical and do not allow for any additional material due to surface porosity, surface profile, variations in level, wastage or any other variations. Apply product to a test area to calculate the exact consumption for the specific substrate conditions and proposed application equipment.

SUBSTRATE QUALITY

- The supporting structure must be of sufficient structural strength to apply all new and existing layers of the roof build up.

- The complete roof system must be designed and secured against wind uplift loadings.

- The substrates must be solvent resistant, uniform, firm, clean, dry, free of grease, bitumen, oil, dust and loosely adhering particles.

- Sheet metal must be cleaned with Sarna Cleaner before adhesive is applied.

SUBSTRATE PREPARATION

Use the appropriate preparation equipment to achieve the required substrate quality.

APPLICATION

Strictly follow membrane installation procedures as defined in method statements, application manuals and working instructions which must always be adjusted to the actual site conditions.

Canister and spray-gun set-up

It is important to set-up the SikaRoof® Adhesive-400 Spray canister adhesive correctly before use to ensure the best possible performance and to avoid leakage or system failure.

| 1. Remove the black cap form the canister valve. |

|

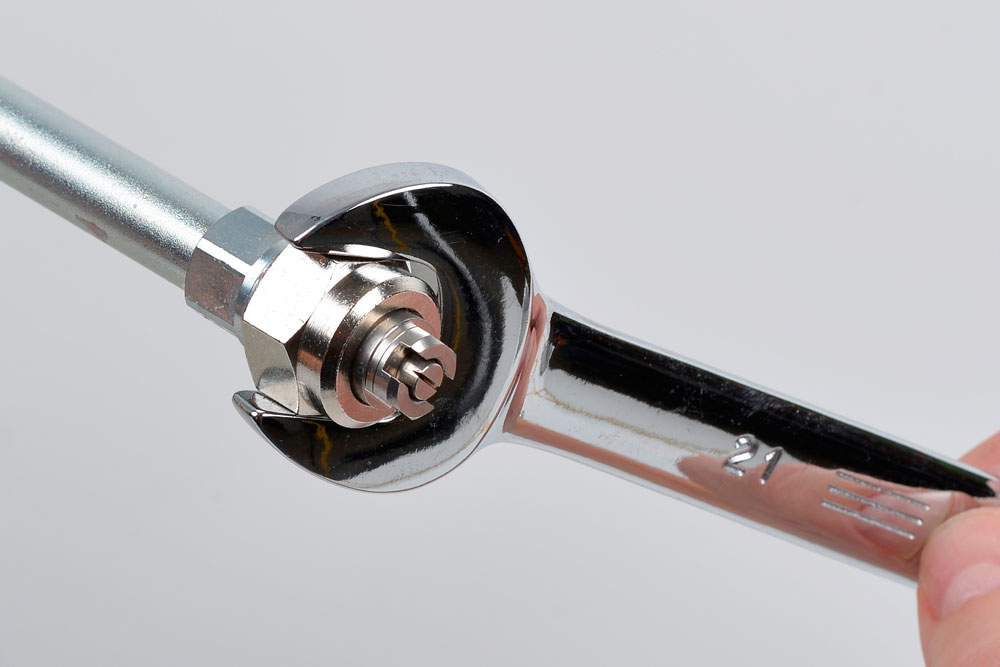

| 2. Attach the rubber hose to the canister valve (using the small nut) and attach the other end of the braided-hose to the spray-gun (using the large nut). Tighten with a spanner. |

|

| 3. Attach the other end of the rubber hose to the spray-gun (using the large nut). Tighten with a spanner. |

|

| 4. Using the locking-nut provided, attach the spray-tip to the end of the spray-gun. |

|

| 5. Fully open the valve on the canister. |

|

| 6. Pull the trigger on the spray-gun to apply adhesive. |

|

| 7. Adjust the spray pattern by turning the black valve on the spray-gun anti-clockwise until a spray pattern width of ~300 mm in width is achieved. |

|

Canister and spray-gun maintenance guide

Once work has been completed, ensure the valve on the canister remains open. Failure to do this may cause the adhesive to block the hose.

| 1. Turn the spray-gun off by turning the black valve clockwise until it is fully closed. |

|

| 2. Unscrew the spray-tip and the end of the spraygun. Clean the spray-tip and the end of the spraygun with Sika Spray Cleaner or Sarna Cleaner using a soft nylon brush to ensure the aperture is clear. This is essential. Failure to clean the spraytip and the end of the spray-gun may result in damage to the aperture and prevent the system from working. Place the spray-tip and locking-nut in a container with a small amount of Sika Spray Cleaner or Sarna Cleaner until it is needed again. Ensure the container is closed and airtight. |

|

Canister flushing system

| 1. Ensure the valve on the canister is completely turned off before attaching the assembly. |

|

| 2. Unscrew the hose from the canister valve. |

|

| 3. Attach the assembly to the valve. Ensure the assembly remains upright whilst the nut is tightened. Attach the hose to the assembly. Ensure the assembly remains upright whilst the hose nut is tightened. |

|

| 4. Check the tap on the assembly is off before applying the Sika Spray Cleaner. Screw the Sika® Spray Cleaner canister into the top of the assembly and open the red valve. |

|

| 5. Aim the spray-gun into a waste container, apply pressure to the trigger on the gun to push Sika® Spray Cleaner trough the hose and gun until the adhesive starts to dispense. Keep pressure on the trigger until the hose and gun are thoroughly cleaned. |

|

Canister system disposal

| 1. The spray canister contains compressed gas. It must be emptied by carefully opening the valve, which will release any excess adhesive and/or pressure. Allow any excess adhesive and/or pressure to fully escape into a suitable container. Leave the valve open. Once the canister is empty and completely depressurised, the circular disk can be pierced using a non-ferrous bar/rod. Allow any remaining adhesive to cure. Dispose or recycle the empty depressurised canister in accordance with local disposal regulations. |

|

Sarnafil® G 410 Membrane (Contact bonding)

Note: Prime only the roofing area where the membrane will be applied on the same day.

- Spray apply 1 coat of SikaRoof® Adhesive-400 Spray directly onto the substrate as a priming coat. Apply 2 coats of adhesive on absorbent substrates.

- Allow to dry completely.

- Lay out the Sarnafil® G 410.

- Align and fold backwards to approximately half its length.

- Spray apply SikaRoof® Adhesive-400 Spray evenly onto the underside of the membrane.

- When the adhesive surface has become ‘tacky’, carefully fold back the Sarnafil® G 410 onto the substrate.

- Press down firmly on the membrane using a suitable pressure roller such as a water-filled, or heavy steel roller (40–50 kg).

- Fold back towards the applied section of membrane the other half of the membrane and repeat the above procedure.

Sarnafil® G 410/Sikaplan® SGK Felt backed membrane (Wet bonding)

Note: Prime only the roofing area where the membrane will be applied on the same day.

- Spray apply 1 coat of SikaRoof® Adhesive-400 Spray directly onto the substrate as a priming coat. Apply 2 coats of adhesive on absorbent substrates.

- Allow to dry completely.

- Lay out the membrane.

- Align and fold backwards to approximately half its length.

- Spray apply SikaRoof® Adhesive-400 Spray evenly onto the underside of the membrane.

- When the adhesive surface is still wet, carefully fold back the membrane onto the substrate.

- Press down firmly on the membrane using a suitable pressure roller such as a water-filled, or heavy steel roller (40–50 kg).

- Fold back towards the applied section of membrane the other half of the membrane and repeat the above procedure.

CLEANING OF TOOLS

Tools and equipment must be cleaned with Sika Spray Cleaner or Sarna Cleaner immediately after use. Purge the adhesive through the hose & application gun (approx. 250 ml) as necessary before and after use.