3D Concrete Printing Technology from Sika

Sika leads the way when it comes to 3D concrete printing technology. The Group has mastered all the process steps needed to print concrete on an industrial scale and the solution has been developed and trialled by Sika’s experts.

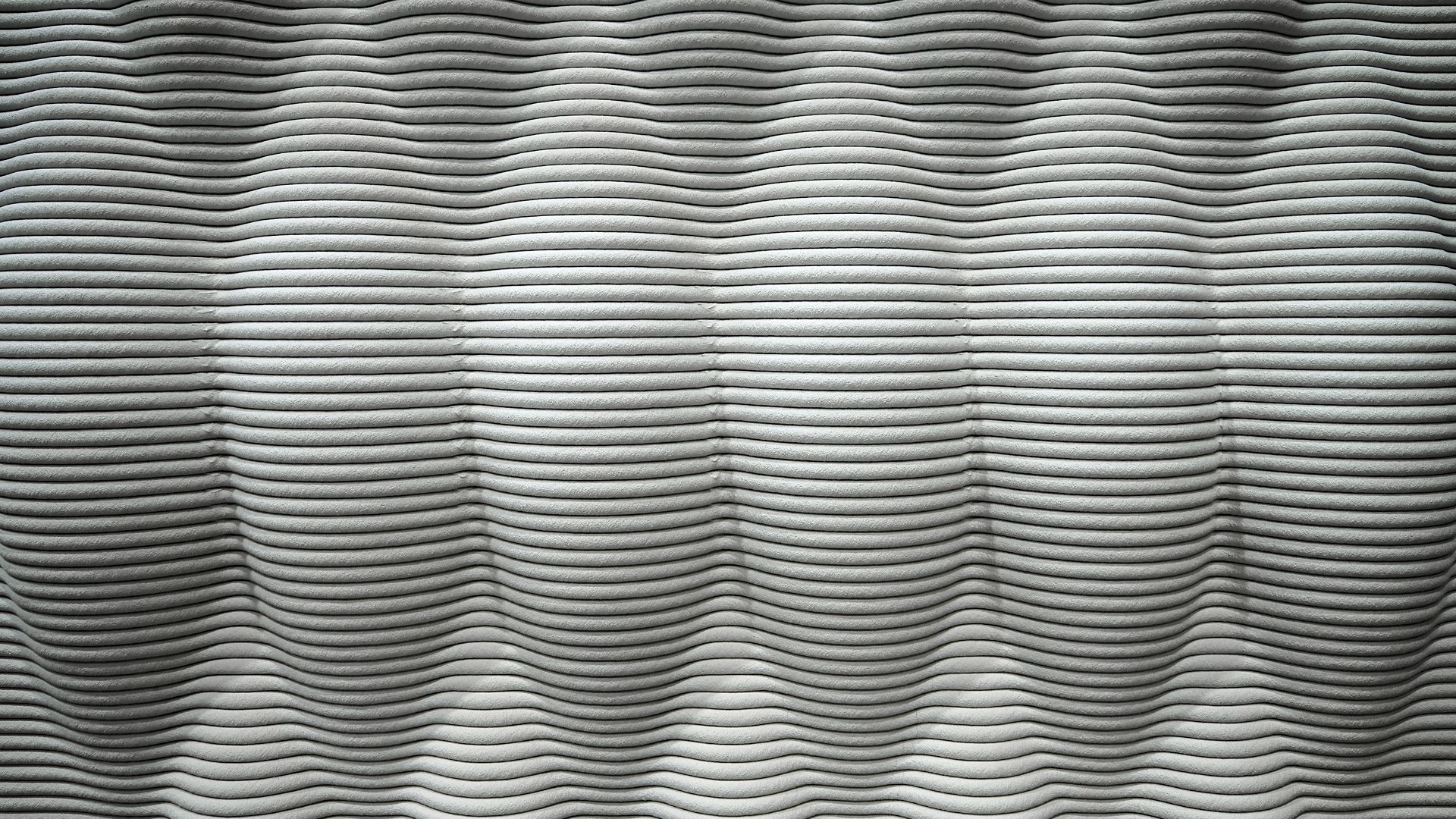

The industrial robot’s arm moves at high speed; under computer control and without a pause. The print head attached to the arm builds up concrete layer upon concrete layer with pinpoint precision. However, the most challenging part of this precision work is what happens in the print head. In this high-performance tool, developed by Sika for 3D concrete printing, a range of additives is mixed with the mortar. The material cures within seconds and bonds with the layer applied previously.

Recommended Products for Concrete 3D Printing

Industrial scale production is the objective

Traditional concrete placing is the most economic construction method. If 3D concrete printing is to compete with this method, then structures need to be printed efficiently. This is precisely what Sika’s technology is designed to achieve. “Right from the start, our aim was to produce a competitive industrial solution using 3D printing,” is how Frank Höfflin, Chief Technology Officer at Sika, describes it. “We have now achieved this ambition. With our technology, it is now possible to print concrete so rapidly, inexpensively, and precisely that it can be used on construction sites.” A fundamental change is taking place in construction, heralded by digitalisation. To quote Frank Höfflin again: “Digitalisation is changing every aspect of construction and the entire life cycle of a building, from the design process and automated construction all the way to maintenance.” Building processes can be optimised and time and money saved; at the same time, these advanced technologies offer greater design flexibility.

The print head developed by the 3D research team at Sika’s Technology Centre in Widen in Switzerland ensures that the printing process is extremely efficient. The flowable mortar is pumped to the 3D printer. Rapid curing, achieved by the precise interaction of the cement and high-grade concrete additives, speeds up the process, and the print head guarantees maximum precision. Sika has made several patent applications and secured for itself the exclusive usage rights to the print head technologies which are essential for the process.

Sika is the technology leader

Thanks to its expertise, Sika is spearheading the digitalisation and industrialisation of concrete construction. And that’s no coincidence. Sika’s entire know-how, built up over decades, has been brought together in its 3D printing technology. The expertise ranges from robotics, the Sika Pulsment process control system, and extruding using the Sika MiniShot system to 3D mortar and the Sika® ViscoCrete® technology, which allows precise control of how the concrete behaves. Sika is the only company capable of supplying all the technologies needed for industrial 3D concrete printing from a single source.

Digitalisation is a mind-set

Digitalisation is the driver for innovation and productivity in the construction industry. Processes which are digitalised from start to finish raise standards and increase construction speed. The value chain is changing fundamentally, from 3D planning to digital processes carried out on the construction site. Digitalisation does not depend on new tools and new software; it is more to do with the mind-set. Initially, it is all a question of the right business model – the process requirements and the essential technologies will follow from this, allowing the construction sector to exploit the massive potential of digitalisation. It is unstoppable.