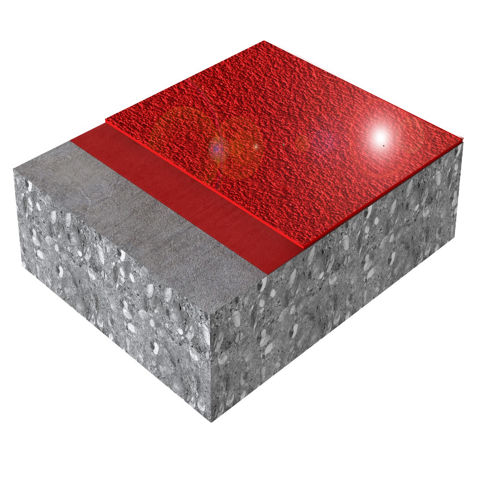

Sikafloor® MultiDur EB-14

Broadcast unicolour epoxy floor covering conforming to OS 8 German standards

Sikafloor® MultiDur EB-14 is a slip resistant, coloured, rigid flooring system based on epoxy resins conforming to OS8 German standards.

- Conforming the OS 8 German standards

- Good chemical and mechanical resistance

- Easy application

- Liquid proof

- Gloss finish

- Easy cleanability