Sikafloor® MultiDur ET-14 ECF

Sikafloor® MultiDur ET-14 ECF is an epoxy, smooth textured, electrostatically conductive flooring system. The system is designed to dissipate electrostatic charges in areas of high explosion risk.

- Thickness ~0.6–0.8 mm

- Electrostatic conductive

- Good chemical and mechanical resistance

- Slip resistant

- Easy to clean

- Waterproof

- Smooth-textured semi-gloss surface finish

Usage

Industrial resin flooring on cementitious substrates for:- Normal up to medium heavy wear

- Automotive production plants

- Chemical production plants

- Laboratories

- Pharmaceutical production areas

- Fibre and textile production

- Explosive storage and handling areas

- Explosive dust environments

- Aircraft maintenance hangars

- Battery-charging rooms

- Computer / server rooms

- Interior use only

Advantages

- Thickness ~0.6–0.8 mm

- Electrostatic conductive

- Good chemical and mechanical resistance

- Slip resistant

- Easy to clean

- Waterproof

- Smooth-textured semi-gloss surface finish

Packaging

Refer to the individual Product Data Sheets

Colour

Available in many colours

Applied colours selected from colour charts will be approximate.

Colour deviations may occur due to carbon fibre filaments.

For colour matching: Apply colour sample and confirm selected colour under real lighting conditions.

When product is exposed to direct sunlight, there may be some discolouration and colour variation, this has no influence on the function and performance of the floor finish.

Appearance

Smooth, textured, semi-gloss

System Details

APPROVALS / STANDARDS

- CE Marking and Declaration of Performance to EN 1504-2 - Surface protection product for concrete - Coating

- CE Marking and Declaration of Performance to EN 13813 - Resin screed material for internal use in buildings

- Slip resistance acc. DIN 51130, Roxeler Baustoffprüfstelle, Test Report Nr. 020109-15-6, May 2016

- Material testing PV 3.10.7, Sikafloor®-262 AS N, HQM, Report No. 14-04-14201871-5

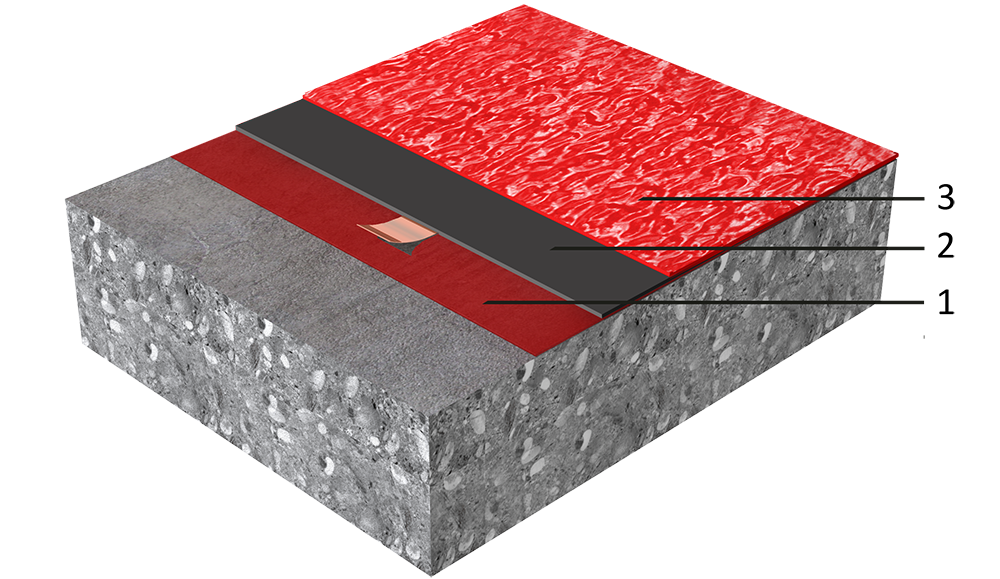

System Structure

Sikafloor® MultiDur ET-14 ECF (~0.6–0.8 mm)

| 1. Primer + earthing connection | Sikafloor®-150/-151 + Sika® Earthing Kit |

| 2. Conductive primer | Sikafloor®-220 W Conductive |

| 3. Conductive wearing finish | Sikafloor®-262 AS N Thixo |

Optional conductive wearing finish:Sikafloor®-262 AS N + 1.25 % Extender T + 2 % Sika® Thinner C

The system structure layers as described in table must not be changed

Composition

Epoxy

Nominal Thickness

~0,6–0,8 mm

Shelf Life

Refer to the individual Product Data Sheets

Storage Conditions

Refer to the individual Product Data Sheets

Shore D Hardness

| ~77 (3 days / +23 °C) | (DIN 53 505) |

Abrasion Resistance

| ~100 mg (CS 10/1000/1000) (7 days / +23 °C) | (EN ISO 5470-1 Taber Abraser Test) |

Compressive Strength

| ~80 N/mm2 (28 days / +23 °C) | (EN 196-1) |

Tensile Strength

| ~40 N/mm2 (28 days / +23 °C) | (EN 196-1) |

Reaction to Fire

| Bfl | (EN 13501-1) |

Chemical Resistance

Resistant to many chemicals. Contact Sika Technical Services for additional information

Thermal Resistance

| Exposure* | Dry heat |

| Permanent | +50 °C |

| Short-term max. 7 days | +80 °C |

Short-term moist/wet heat* up to +80 °C where exposure is temporary (i.e. during steam cleaning etc.)

*No simultaneous chemical and mechanical exposure.

USGBC LEED Rating

Conforms to the requirements of LEED EQ Credit 4.2: Low-Emitting Materials: Paints & Coatings SCAQMD Method 304-91 VOC Content < 100 g/l

Skid / Slip Resistance

| R9 | (DIN 51130) |

Electrostatic Behaviour

Resistance to ground1 | Rg < 109 Ω | (IEC 61340-4-1) |

Typical average resistance to ground2 | Rg < 106 Ω | (DIN EN 1081) |

1 In accordance with IEC 61340-5-1 and ANSI/ESD S20.20.

2 Readings may vary, depending on ambient conditions (i.e. temperature, humidity) and measurement equipment.

Application

Ambient Air Temperature

+10 °C min. / +30 °C max.

Relative Air Humidity

80 % max.

Dew Point

Beware of condensation. The substrate and uncured applied floor materials must be at least +3 °C above dew point to reduce the risk of condensation or blooming on the surface of the applied product.

Substrate Temperature

+10 °C min. / +30 °C max.

Substrate Moisture Content

≤4 % parts by weight. The following test methods can be used: Sika®-Tramex meter, CM - measurement or Oven-dry-method. No rising moisture according to ASTM (Polyethylene-sheet).

Waiting Time / Overcoating

Before applying Sikafloor®-220 W Conductive on Sikafloor®-150/151 allow:

| Substrate temperature | Minimum | Maximum |

| +10°C | 24 hours | 4 days |

| +20°C | 12 hours | 2 days |

| +30°C | 8 hours | 1 days |

Before applying Sikafloor®-262 AS N Thixo on Sikafloor®-220 W Conductive allow:

| Substrate temperature | Minimum | Maximum |

| +10°C | 26 hours | 7 days |

| +20°C | 17 hours | 5 days |

| +30°C | 12 hours | 4 days |

Times are approximate and will be affected by changing ambient conditions particularly temperature and relative humidity.

Applied Product Ready for Use

| Temperature | Foot traffic | Light traffic | Full cure |

| +10 °C | ~30 hours | ~5 days | ~10 days |

| +20 °C | ~24 hours | ~3 days | ~7 days |

| +30 °C | ~16 hours | ~2 days | ~5 days |

Times are approximate and will be affected by changing ambient conditions particularly temperature and relative humidity.

Consumption

| Layer | Product | Consumption |

| 1.Primer | Sikafloor®-150/-151 | 1–2 × ~0.3–0.5 kg/m2 |

| Levelling (if required) | Sikafloor®-150/-151 levelling mortar | Refer to PDS of Sikafloor®-150/-151 |

| Earthing connection | Sika® Earthing Kit | 1 earthing point per ~200–300 m2. 2 per room minimum |

| 2.Conductive primer | Sikafloor®-220 W Conductive | 1 × 0.08–0.10 kg/m² |

| 3. Conductive wearing finish | Sikafloor®-262 AS N Thixo, or Sikafloor®-262 AS N + 1.25% Extender T + 2 % Sika® Thinner C | 1 × 0.75 kg/m² |

These figures are theoretical and do not allow for any additional material due to surface porosity, surface profile, variations in level or wastage etc.

CLEANING

Refer to Information Manual: Sikafloor®-Cleaning Regime