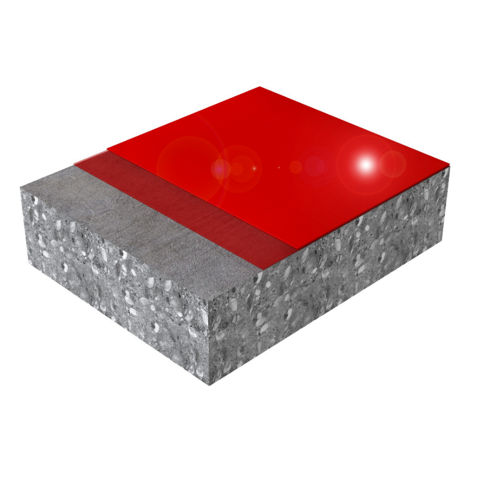

Sikafloor® MultiDur ES-20

Smooth unicolour epoxy floor covering

Sikafloor® MultiDur ES-20 is a 2-part epoxy coloured resin based self-smoothing floor finish that can provide a hard wearing, seamless, low maintenance, smooth gloss finish. For medium - heavy wear conditions. Thickness 1.5–3.0 mm. Internal use.

- Seamless and hygienic

- Good chemical and mechanical resistance

- Easy application

- Waterproof

- Gloss finish

- Easy cleanability

- Low maintenance