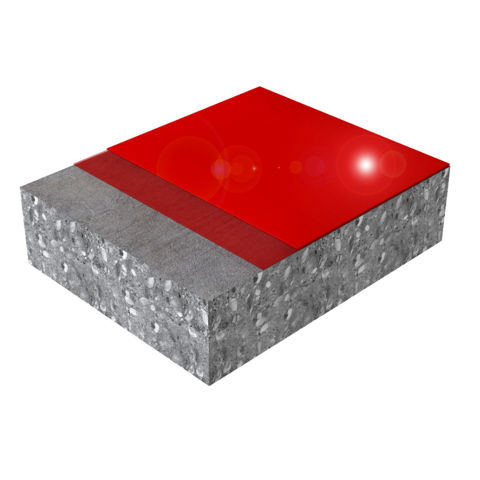

Sikafloor® MultiDur ES-21

Smooth unicolour epoxy floor covering

Sikafloor® MultiDur ES-21 is a smooth coloured rigid system for flooring applications

- Good chemical and mechanical resistance

- Good wear and abrassion resistance

- Easy application

- Liquid proof

- Gloss finish

- Easy cleanability

- Colour options