What is the Process for a Concrete Repair Area?

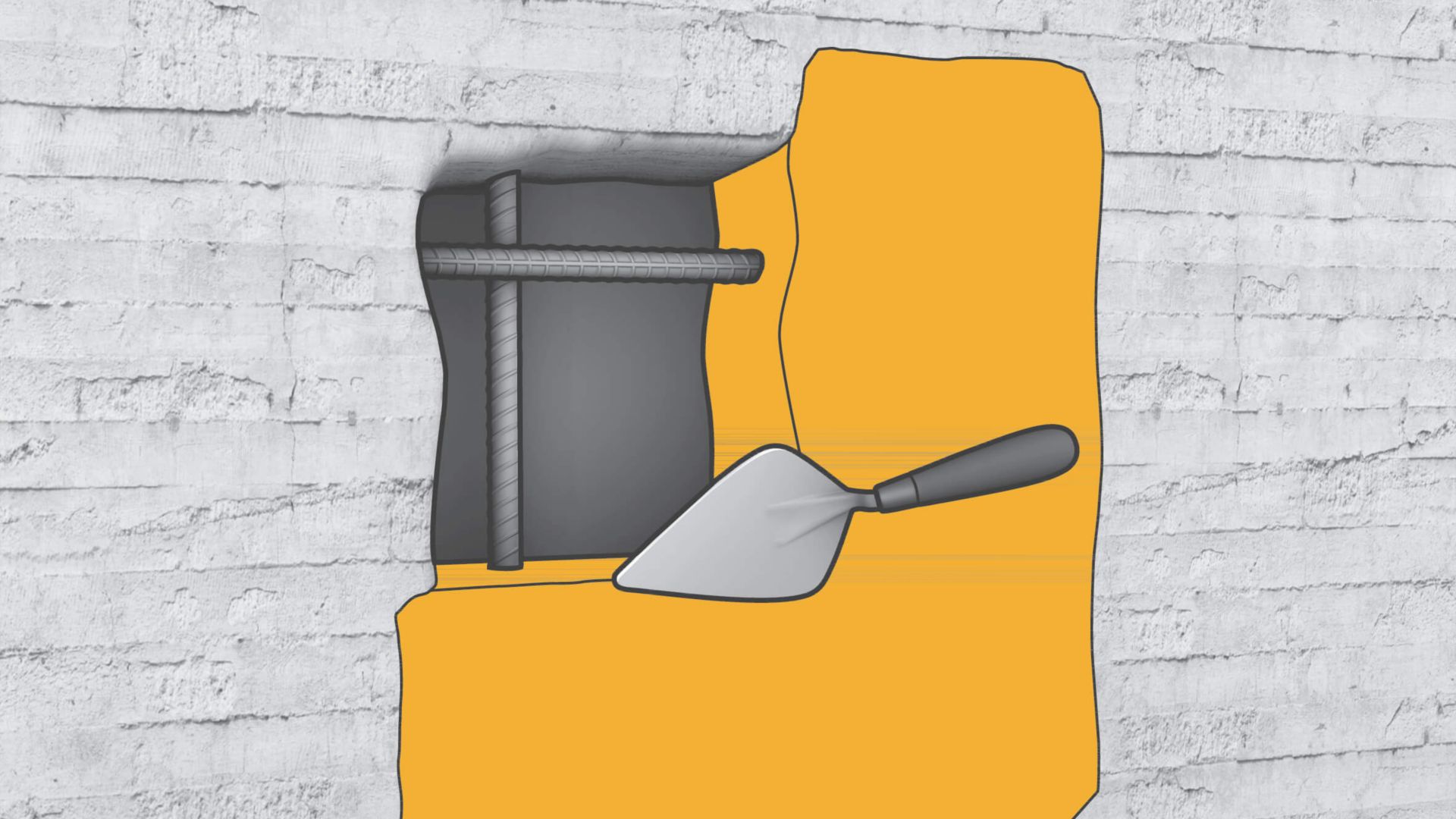

Corrosion protection and bonding primers are used for bonding concrete repair mortars to existing cementitious or steel substrates and providing additional corrosion protection to reinforcement steel, especially in areas of low concrete cover and in the presence of chlorides. Exposed reinforcement steel bars should be properly prepared and protected with anti-corrosion slurry to further enhance the repair process.

Advantages:

- Ready to mix, easy to apply

- Adjustable consistency

- Active corrosion inhibitors for added protection

- Can be sprayed or manually applied

Repair mortars are specifically designed for restoring or replacing the original profile and function of the damaged concrete. They help to repair concrete defects, improve appearance, restore structural integrity, increase durability and extend the structure’s longevity.

Sika concrete repair mortars are suitable for restoration work, repair of spalling and damaged concrete in all types of structures including buildings, bridges, infrastructure and super-structures.

Advantages:

- Easy to mix and apply

- Pre-bagged for quality, just add water

- High mechanical properties

- Can be overcoated with Sika leveling mortars

- Can be sprayed or manually applied

- Pure cement-based, cementitious, polymer-modified and epoxy-based repair mortar materials available

When concrete needs to be coated or levelled, special mortars are necessary to fill the surface pores. Sika pore fillers and leveling mortars are thin layer renders designed to repair minor defects, such as repairing pores and honeycombed concrete.

Advantages

- Easy to mix and apply

- Pre-bagged for quality, just add water

- Can be overcoated with Sika protection coatings

- Can be sprayed or manually applied

The most common causes of steel reinforcement corrosion in concrete are caused by carbonation or chloride ingress with water. Understanding the root cause of steel corrosion determines the most effective repair and protection strategy.

Sika provides a full range of products to prevent further corrosion of steel reinforcement by properly protecting the concrete around it. Our corrosion management systems allow flexibility to select the most cost effective, suitable solutions for your project’s needs.

Why Concrete Repairs Fail and Why Fix them?

Deterioration of concrete is largely due to:

Chemical degradation, e.g. chemical exposure, alkali aggregate reactions, bacterial action

Corrosion of the reinforcement steel, e.g. carbonation, chlorides, stray electrical current

Mechanical attack, e.g. impact, overloading, movement, earthquake, explosion

Physical damage, e.g. freeze/thaw action, thermal movements, shrinkage, abrasion, wear

Underlying contributors, e.g. poor construction, design faults, lack of maintenance

Reasons for concrete repair:

Replace defective concrete

Restore structural integrity

Restore aesthetic appearance

Restore geometric appearance

Restore durability