When performance, durability, and precision matter, Sika cementitious grouts deliver exceptional results. Engineered to meet the most demanding structural requirements, our grouts provide reliable load transfer, shrinkage‑compensated stability, and superior bonding across a wide range of applications. From critical infrastructure projects and industrial machinery bases to wind‑turbine foundations and precast concrete installations, our products are designed to withstand heavy loads, environmental stressors, and long-term service conditions.

With a focus on consistency, ease of placement, and lasting integrity, Sika cementitious grouts ensure that every project achieves both structural performance and enduring durability.

Want to know more about grouts?

Why Use a Cementitious Grout

Structural application – designed to transfer loads safely.

Shrinkage‑compensated to avoid gaps, settlement or cracking.

Durable under demanding conditions (static loads, cyclic loads, weather exposure).

Versatile – can be adapted to general grouting, specialist infrastructure like wind‑turbine bases, roads, landscaping.

Where can cementitious grouts be used?

Sika has a full range of cementitious grouts, epoxy grouts, polymethyl methacrylate (PMMA) grouts and polyurethane grouts to suit your project needs.

General grouting

Wind turbine grouting

Road work and landscaping

Micro concrete

Concrete Repair and New Construction Grouts

Sika’s cementitious grouts are designed to deliver high-performance solutions for both concrete repair and new construction projects. Formulated with precision, these grouts offer excellent flowability, controlled expansion, and superior bond strength — ensuring complete contact between structural elements and long-term load transfer without shrinkage or voids.

Ideal for grouting under baseplates, columns, and precast elements, they provide reliable strength development and durability even in demanding site conditions.

Precast Concrete Grouts

Sika’s cementitious grouts for precast concrete applications are formulated to provide strength, flow, and precision where it matters most — between critical connections and load-bearing elements. These high-performance materials ensure complete void filling, reliable bond strength, and long-term durability in both structural and architectural precast assemblies.

Whether used for jointing, segmental repair, or reinforcement connection, Sika and Parex grouts each designed to meet specific performance criteria — from rapid strength gain to high flow and precision placement. Together, they ensure efficient installation, structural reliability, and a durable connection across all precast elements.

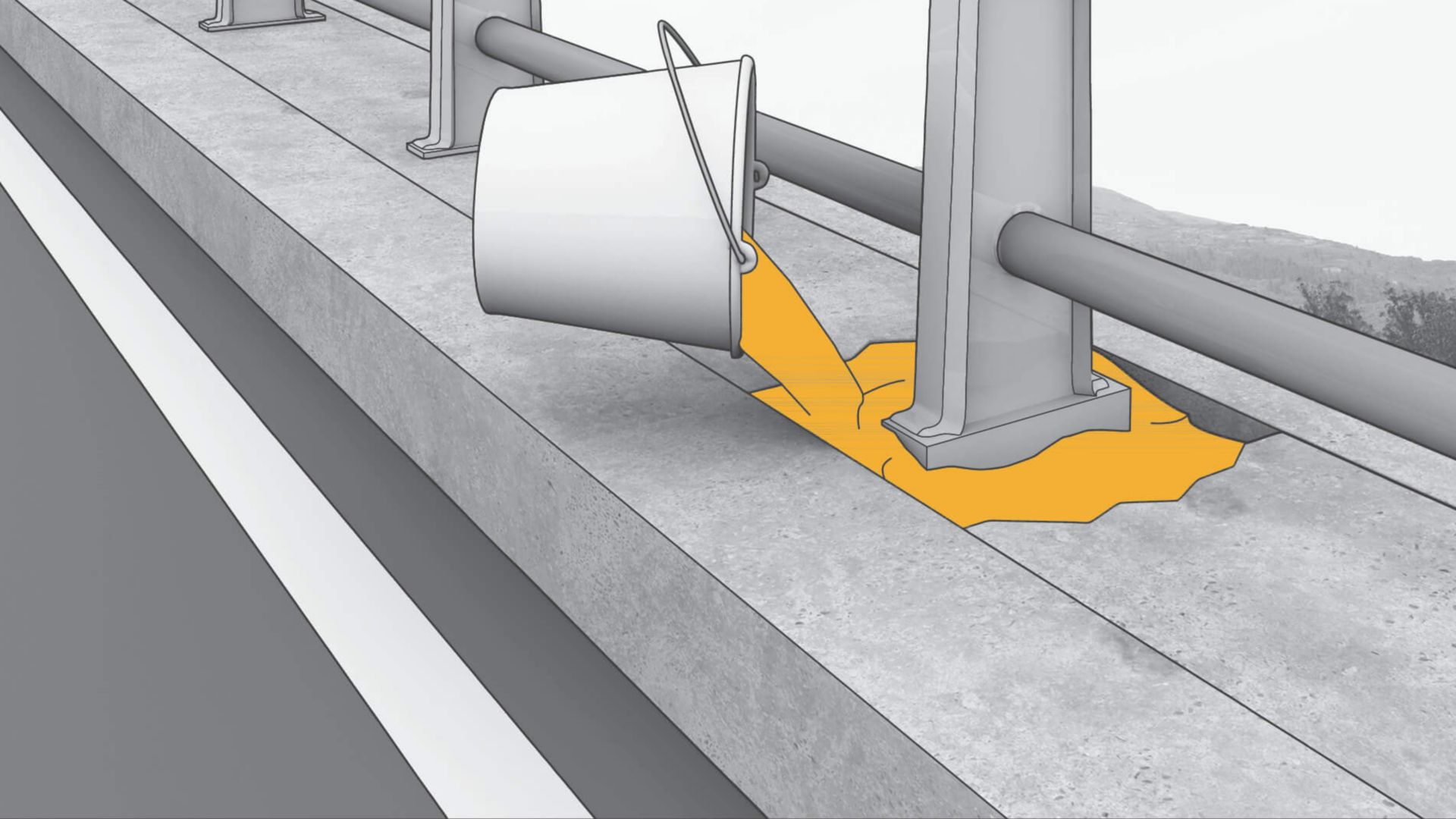

Highway Construction and Maintenance Grouts

Sika’s cementitious grouts for highway and civil infrastructure applications are engineered for strength, precision, and durability under the most demanding service conditions. Designed to withstand heavy traffic loads, vibration, and environmental exposure, these grouts provide reliable performance for both new construction and maintenance works across bridges, carriageways, and roadside structures.

From structural anchoring and bearing plate installation to void filling and cable duct grouting, Sika and Parex solutions offer excellent flow characteristics, controlled expansion, and rapid strength development.

Wind Installation Grouts

Sika’s cementitious grouts for wind energy installations are developed to meet the high-performance demands of modern turbine foundations. Engineered for strength, precision, and long-term durability, they provide reliable load transfer and structural stability in both onshore and offshore environments. With proven resistance to dynamic loads, fatigue, and environmental exposure, Sika grouts help ensure the safe and lasting operation of renewable energy assets.

Offshore Wind Installations

In offshore environments, grouting materials must perform under extreme conditions — high loads, wave impact, and continuous exposure to saltwater. Sika’s offshore wind range delivers exceptional flowability, controlled expansion, and outstanding long-term durability. These high-strength grouts are trusted worldwide for grouting turbine transition pieces, monopiles, and jacket foundations.

Onshore Wind Installations

For onshore wind farms, Sika’s cementitious grouts provide rapid strength gain and long-term resilience against vibration and environmental stresses. Sika solutionsensure full load transfer and secure anchorage between turbine base plates and concrete foundations — optimising performance and extending the service life of each installation.