Sikafloor® PurCem® HS-21

Sikafloor® PurCem® HS-21 system is made with polyurethane cement technology and is part of the Sikafloor® PurCem® flooring range. The Sikafloor® PurCem® HS-21 system is especially designed to withstand chemical attack, high impact and can be used in wet and dry processing plants.

The system is composed of an highly durable polyurethane cement body coat, it has an aesthetic, easy to clean and smooth surface, providing medium slip resistance. Is typically installed at 4 to 6 mm thick.

- High chemical resistance. Resists a wide range of organic and inorganic acids, alkalis, amines, salts and solvents

- Good temperature resistance

- High mechanical and abrasion resistance

- Easy application

- Easy to clean and maintain

- Seamless, non taint, odourless

- Smooth, matt surface

- Tolerant to moisture in the substrate

- Very good life cycle cost performance

Usage

- Food processing plants, in wet or dry process areas, freezers and coolers, thermal shock areas

- Chemical plants

- Laboratories

- Workshops

Advantages

- High chemical resistance. Resists a wide range of organic and inorganic acids, alkalis, amines, salts and solvents

- Good temperature resistance

- High mechanical and abrasion resistance

- Easy application

- Easy to clean and maintain

- Seamless, non taint, odourless

- Smooth, matt surface

- Tolerant to moisture in the substrate

- Very good life cycle cost performance

Packaging

Please refer to the individual Product Data Sheet

Colour

Beige, Golden Yellow, Carmine Red, Ultramarine Blue, Yellow Green, Pebble Grey, Dusty Grey, Agate Grey

Appearance

Smooth surface, matt finish

System Details

ENVIRONMENTAL INFORMATION

- VOC emission certificate according to AgBB und DIBt approval requirements, Eurofins, 4.1.2012

- VOC emission certificate class A+ according to French regulation, Eurofins, 22.06.2012

APPROVALS / STANDARDS

- Screed material for floor screeds according to EN 13813: 2002, Declaration of Performance 02 08 02 02 001 0 000002 1088 and provided with the CE-marking.

- Surface protection coating for concrete according to EN 1504-2:2004, Declaration of Performance 02 08 02 02 001 0 000002 1088, certified by notified factory production control body 0086, certificate of conformity of the factory production control 541325, and provided with the CE-marking.

- Conforms to the requirements of: EN1186, EN 13130, prCEN/TS 14234 and the Decree on Consumer Goods, representing the conversion of directives 89/109/EEC, 90/128/EEC and 2002/72/EC for contact with food stuffs. Test report by ISEGA, 32758 U11 and 32759 U11, both dated December 6th, 2011.

- Certified as suitable for use in food and beverage facilities that operate in accordance with a HACCP based Food Safety Programme.

- Compliant with USDA flooring requirements

- Canadian Food Inspection Agency acceptance for use in food plants in Canada.

- British Standards Specifications (BSS) acceptance for use in the UK. Campden and Chorleywood Food Research Association, Ref. S/REP/125424/1a and 2a, dated 8th February, 2012

- Fire classification report according to EN 13501-1 from Exova Warrington Fire for Sikafloor®-21 PurCem® No.317047, dated 24th of March, 2012

- Liquid water transmission rate test report from the Technology Centre, Ref. 15456 dated January 25th, 2012

- Abrasion resistance tests performed by Face Consultants Ltd., according to BS 8204-2:2003, report ref. FC/12/3850, dated January 17th, 2012. (Tests performed on Sikafloor® -20/21 PurCem®)

- Impact resistance values tested at PRA, Ref. No. 75221-151, dated January 11th, 2012

- Slip resistance properties according to DIN 51130 tested at MPI (Materialprüfung und Entwicklung), test reports refs. No. 12-6639-S/12 and 12-6641-S/12, dated August 7th, 2012.

- GMP "Class A in operation" certified in accordance with EC-GMP Annex 1, (Clean Room Suitable Materials ® tested, report no. SI 1403-695.

- Cleanibility. Clean Room Suitable Material (Riboflav in test) test report no. SI 1403-695, Fraunhofer Institute for Manufacturing and Engineering and Automation IPA.

- Biological resistance. Clean Room Suitable Material test report no. SI 1403-695, Fraunhofer In- stitute for Manufacturing and Engineering and Automation IPA.

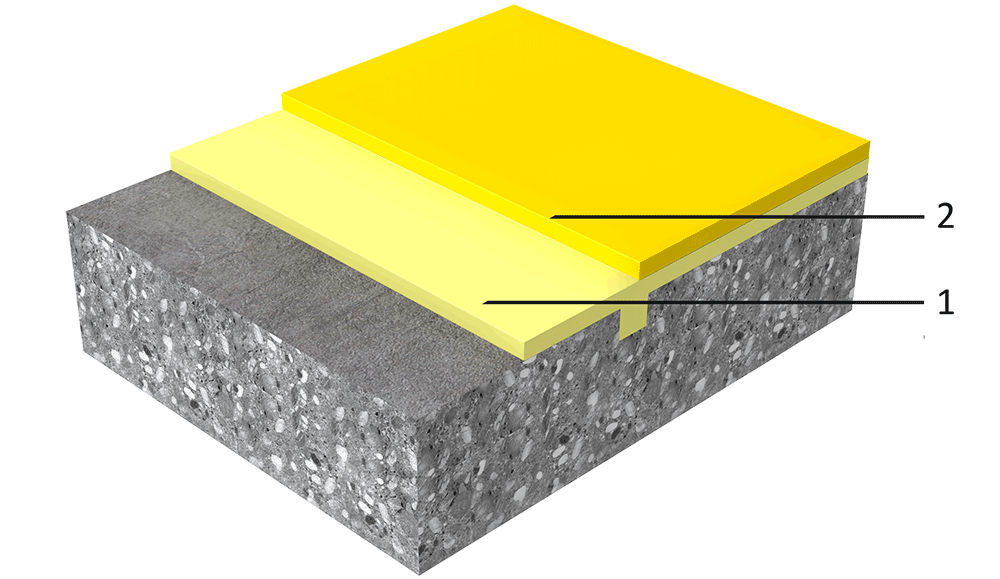

System Structure

Sikafloor® PurCem® HS-21

| Layer | Product |

| 1. Scratch coat | Sikafloor®-21 PurCem® |

| 2. Body coat | Sikafloor®-21 PurCem® |

As optional primers Sikafloor® -150/-151 + quartz sand 0.3–0.8 mm broadcast to excess can be used. Please refer to the individual Product Data Sheet.

Composition

Water-based polyurethane cement hybrid

Nominal Thickness

~ 4-6 mm

Volatile organic compound (VOC) content

Very low content of volatile organic compounds, it fulfils the stringent demands for indoor air quality and low VOC emitting products AgBB.

Shelf Life

Please refer to the individual Product Data Sheet

Storage Conditions

Please refer to the individual Product Data Sheet

Water Absorption

| 0 % | (CP BM2/67/2) |

Abrasion Resistance

Class “Special” Severe abrasion resistance |

| AR 0.5 |

| Class A6 |

| < 900 mg (H-22/1000/1000) |

Resistance to Impact

Class III (≥ 20Nm) |

| 2 pounds/30 inches (3 mm thick) |

Indentation

0 | (MIL – PFR 24613) |

Compressive Strength

| >55 N/mm2 after 28 days at +23°C / 50% r.h. | (BS EN 13892-2) |

Tensile Adhesion Strength

> 2.0 N/mm2 | (EN1542) |

Reaction to Fire

Bfl-s1 | (EN 13501-1) |

Chemical Resistance

Please refer to Sikafloor® PurCem® chemical resistance guide. Contact Sika technical service for specific information.

Thermal Resistance

| 4 mm | 6 mm |

| -15 °C to +70 °C | -25 °C to +70 °C |

The product is resistant to short term contact with temperatures of +90°C, mainly during the cleaning regimes.

Capillary Absorption

< 0.002 kg/(m2×h0,5) | (EN 1062-3) |

USGBC LEED Rating

Conforms Section EQ (Indoor Environmental Quality), Credit 4.2 Low-Emitting Materials Paints and Coatings. Calculated VOC content ≤ 50 g/l

Coefficient of Friction

Rubber: | 0.5 |

Steel: | 0.3 |

Skid / Slip Resistance

R 10 |

SRV Dry | SRV Wet |

| 70 | 60 |

Application

Product Temperature

Please refer to the individual Product Data Sheet

Ambient Air Temperature

+10 °C min / +40 °C max

Relative Air Humidity

80 % max

Dew Point

Beware of condensation!

The substrate and uncured floor must be at least 3 °C above dew point to reduce the risk of condensation or other disturbance of the surface on the floor finish.

Substrate Temperature

+10 °C min / +40 °C max

Substrate Moisture Content

Sikafloor® PurCem® HS-21 can be installed on substrates with higher moisture content. The substrate needs to be visibly dry and have an adequate pull-off strength min 1.5 N/mm2. No ponding water. Check for rising moisture.

Applied Product Ready for Use

| Temperature | Foot traffic | Light traffic | Full cure |

| +10 °C | ~20 hours | ~34 hours | ~7 days |

| +20 °C | ~12 hours | ~16 hours | ~4 days |

| +30 °C | ~8 hours | ~14 hours | ~3–4 days |

Note: Times are approximate and will be affected by changing ambient conditions and substrate conditions

Consumption

| Layer | Product | Consumption |

| 1. Scratch coat | Sikafloor®-21 PurCem® | ~1.0-3.0 kg/m2 |

| 2. Body coat | Sikafloor®-21 PurCem® | ~1.9 kg/m2/mm |

Consumptions are theoretical and do not include any wastage, additional material need due to porosity, substrate profile etc.

CLEANING

Please refer to Sikafloor®- Cleaning Regime.