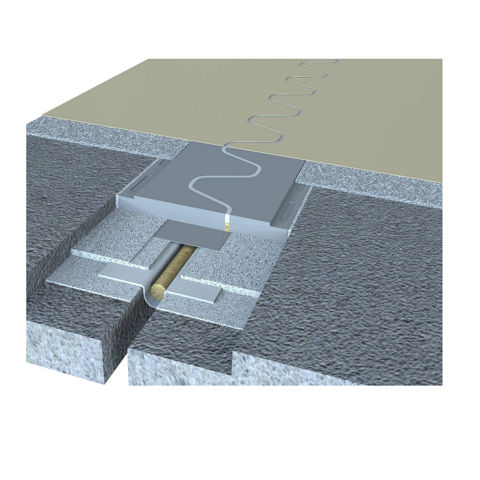

Sika® FloorJoint PB-30 PD

CARBON FIBRE PREFABRICATED FLOOR JOINT SYSTEM FOR CAR PARKS

Sika® FloorJoint PB-30 PD is a carbon fibre reinforced polymer (CFRP) composite, prefabricated, floor joint system with high mechanical resistance for normal up to medium wear loading conditions. Its sinusoidal surface tooth profile allows for an improved load distribution and results in minimum vibrations under direct car traffic. Gap widths: 0–60 mm.

- Grindable profile for level integration into the floor surface

- Reduced vibrations under direct car traffic

- Thermal expansion coefficient similar to resin based floors

- Easy to install / Easy to repair

- Short down time - Trafficable after 24 hours

- Waterproof system design possible

- High chemical resistance

- Non corroding

- High mechanical resistance